IP65 Certification Introduction (IP65/IP66/IP67/IP68 Protection class)

IP65 Certification Introduction(IP65/IP66/IP67/IP68 Protection class),Dustproof, waterproof grade, IP protection, IP 65 technology, NEMA Introduction, IP 65 technology, IP 65 approved

IP65 Certification Introduction(IP65/IP66/IP67/IP68 Protection class)

| Prime number (anti-hard object) | Definition | Minor number (anti-liquid) | Definition |

|

Dust, but allows a small amount into the (harmless accumulation) |

|

Prevent from all sides of low-pressure water spray, but allow a few enter |

|

|

Completely dustproof |

|

Prevent powerful spout, such as planking, but allowing a few enter used |

|

|

15 centimeters to within one metre of SRM can waterproof, temporarily during the testing for 30 minutes | ||

|

|

But long-term bear heavy pressure |

IP protection class (dust and water) is defined

IPxx(IP65、IP66、IP67、IP68)

Dust level (the first X that)

0: No protection

1: to prevent the invasion of large solid

2: to prevent the intrusion of solid medium-sized

3: to prevent intrusion into the small solid

4: Prevention of solid objects greater than 1mm into

5: to prevent the accumulation of harmful dust

6: completely prevent dust entering

Waterproof Grade (the second X that)

1: No water droplets trickle-down effect to the shell

2: When the shell tilted to 15 degrees, dropping to the shell has no effect on water droplets

3: water or rain water from 60 degrees to the shell on the corner of no effect

4: Liquid splashed from any direction without damage to the outer shell of

5: wash with water without any harm to

6: can be used for the cabin environment

7: flooding tolerance in a short time (1m)

8: in the long immersion under pressure

NEMA introduction

·National Electrical Manufacturing Association (NEMA)

·and IP protection code comparison

IP 65=NEMA4,4X

IP 67=NEMA6,6P

IP 65 technology

Test Method / Specification :

| Testing method: | Reference to the international electrotechnical commission (IEC) 60529 2.1 version: 2001-2002 - IP 65 |

| 1. To prevent contact dangerous parts of test: | |

| Testing method: | IEC 60529 2.1 version: 2001-2002 - IP6X |

| 1 mm in diameter, the test length of 100 mm or embedded with wire advancing any holes on the chassis, and "IEC 60529 2.1 edition :2001-2002, " the strength specified in Table 6, testing whether the exposure wire The risk of power to the chassis components. | |

| Test intensity: | 1 N ±10% |

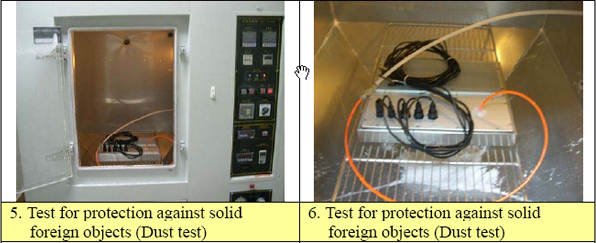

| 2. Prevent hard eyewinker test: | |

| Testing method: | IEC 60529 2.1 version: 2001-2002 - IP6X (dustproof testing) |

| Dust type: | Talcum powder |

| Dust capacity: | 2kg |

| Machine room size: | 1m3 |

| Maximum pressure: | -20 mbar |

| During the test: | 8 hours |

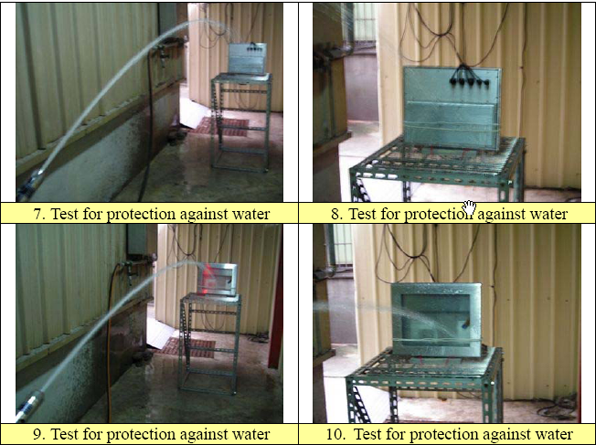

| 3. Waterproof test: | |

| Testing method: | Reference IEC 60529 2.1 version: 2001-2002 - IPX5 |

| Waterproof test: | |

| Test mode: | With a test specification specified standard test nozzle, from all feasible direction of water cabinet. |

| Nozzle diameter: | 6.3mm |

| Spray speed: | 12.5 per minute± 5% |

| The nozzle surface distance from the cabinet: | 2.5 m ~ 3 m |

| The actual water column core: | About 40 mm diameter circle, distance nozzle 2.5 m |

| During the test: | 3 minutes (minimum) |

IP 65 Technology

IP 6X test

IP X5 test

IP 65 approved

1. inside the machine for the pressure 0.006Mpa, for 60 seconds down to 0.005Mpa.

2. positive pressure inside the machine 0.010Mpa, for 60 seconds down to 0.008Mpa.

3. for the pressure inside the machine 0.006Mpa, there will be bubbles on the water.

4. no pressure inside the machine, and no air bubbles in water, for 30 minutes yet to find water seepage.